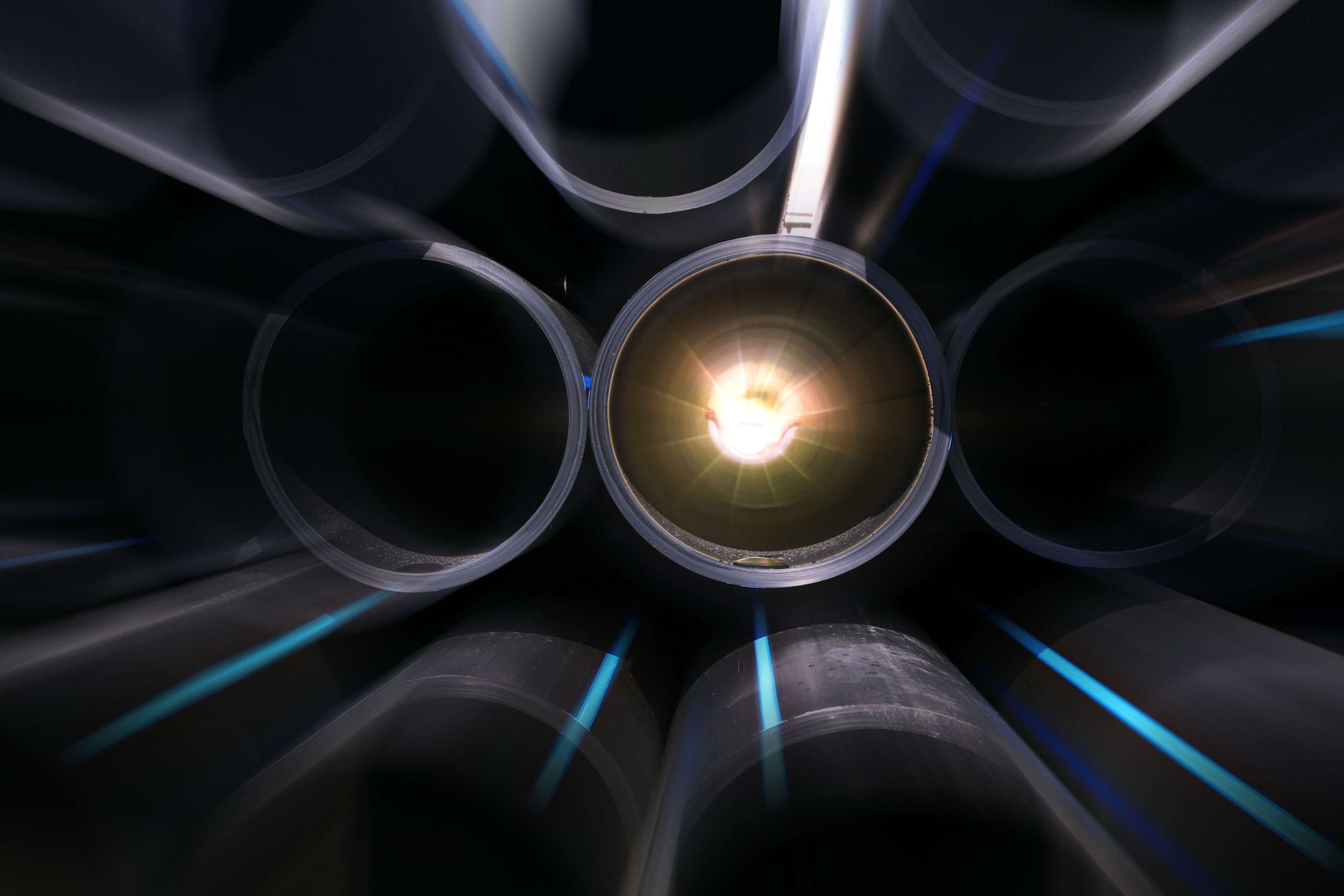

While the use of ultrasonics had increase in past decades within NDT Industry in many different kinds of applications and industries, the development of new technologies has been following the trend, both for services and industrial systems. Whereas most of Ultrasonics users are familiar with conventional UT commonly used with monolithic probes, the arrival of Phased Array brought new possibilities to Ultrasonics inspection.

The main advantages of Phased Array Ultrasonics (PAUT) over conventional methods and other NDT technics are the flexibility it offers. As it uses a probe with many elements, Phased array can steer a beam for better coverage and without having to move the probe, hence avoiding cumbersome mechanical steering using servo motors like conventional UT. This brought the ability to control the direction and shape of the generated beam angle to ensure that it is perpendicular to the face of an expected discontinuity. As it can deviate a beam simply by computer control, it also provides electronic focusing to optimize sensitivity and coverage. Both beam steering and beam focusing used with Phased Array will brought advantages in industrial applications.

Phased Array Ultrasonics brings faster inspection:

High speed Imaging:

Due to a high rate of electronic scans or focusing, leading to a wider area of inspection than with conventional UT, digital feedback of B-Scan and C-Scan are generated with a high throughput, in real time.

On top of a high-speed processing, Phased Array Ultrasonics is known to deliver good imaging solutions.

Reliable test results:

Reducing or removing mechanical scanning increase the reliability of measurements providing better repeatability, often for complex geometries parts. Thus, leading to a lower risk of a loss of coupling whenever a probe is in movement.

Phased Array Ultrasonics provides a better Probability of Detection (PoD):

Better sensitivity, coverage, can be done using Phased Array Ultrasonics because a probe is used to control the direction and shape of the generated ultrasonic beam. Through optimisation of the beam angle to ensure that it is perpendicular to the face of an expected discontinuity, it provides better results and also allow the inspection of complex geometries.

Focusing beam can be adapted with shape, width and depth for a better view of internal defects when performing volumetric inspection. As Phased Array can process data at very high speed, it provides a higher ability to detect flaws at higher speed.

Both electronic scanning and focusing can significantly improve signal-to-noise ratio in challenging applications, thank to Phased Array flexibility and technology.