Principle

--------------------------------------------------------------------------------------------------------------------------------------------------

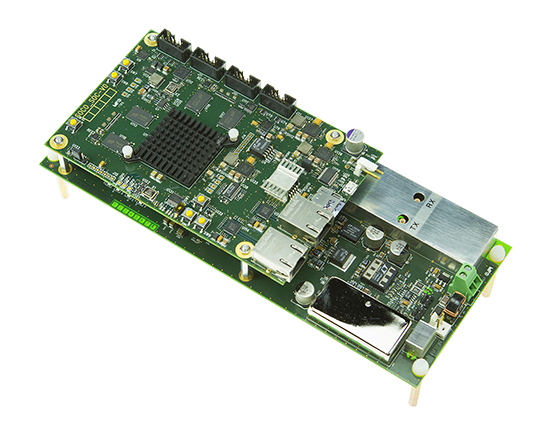

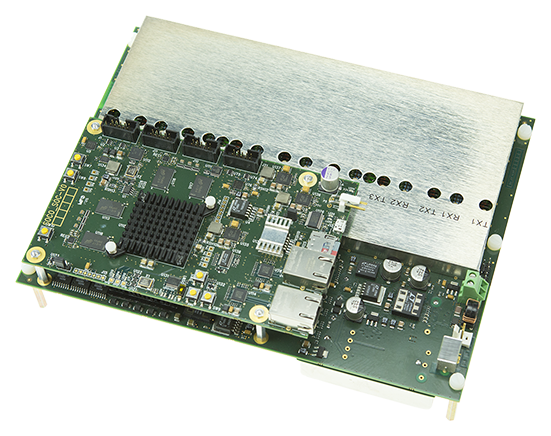

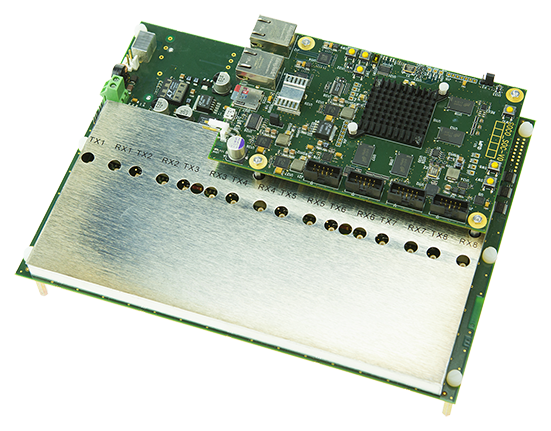

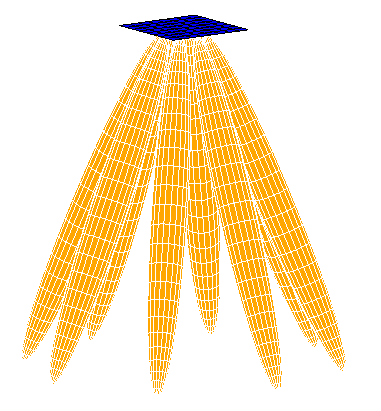

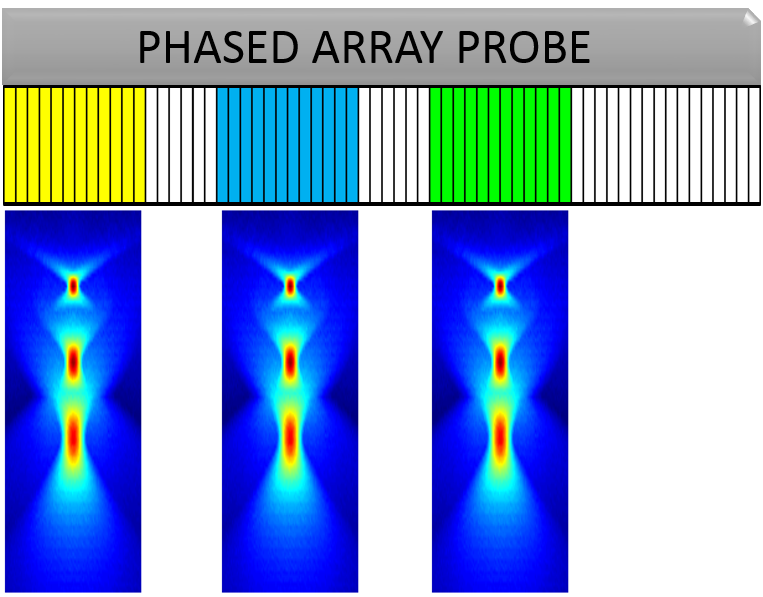

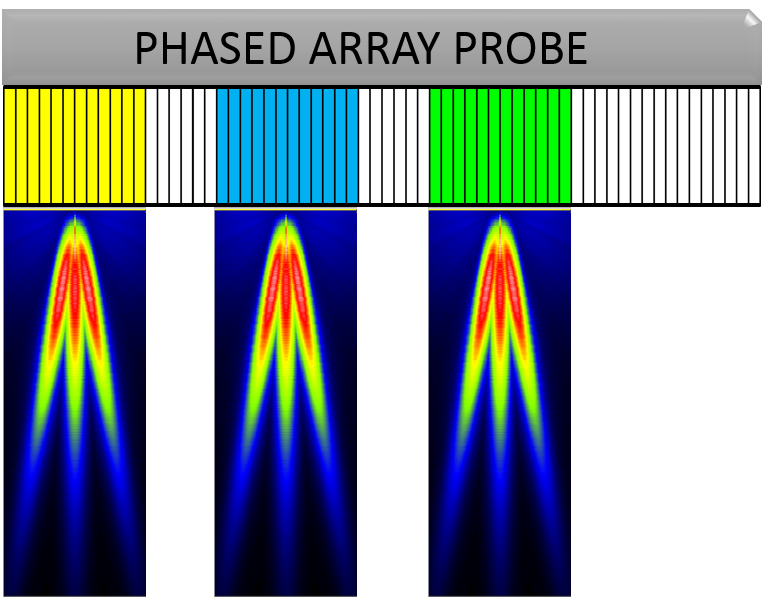

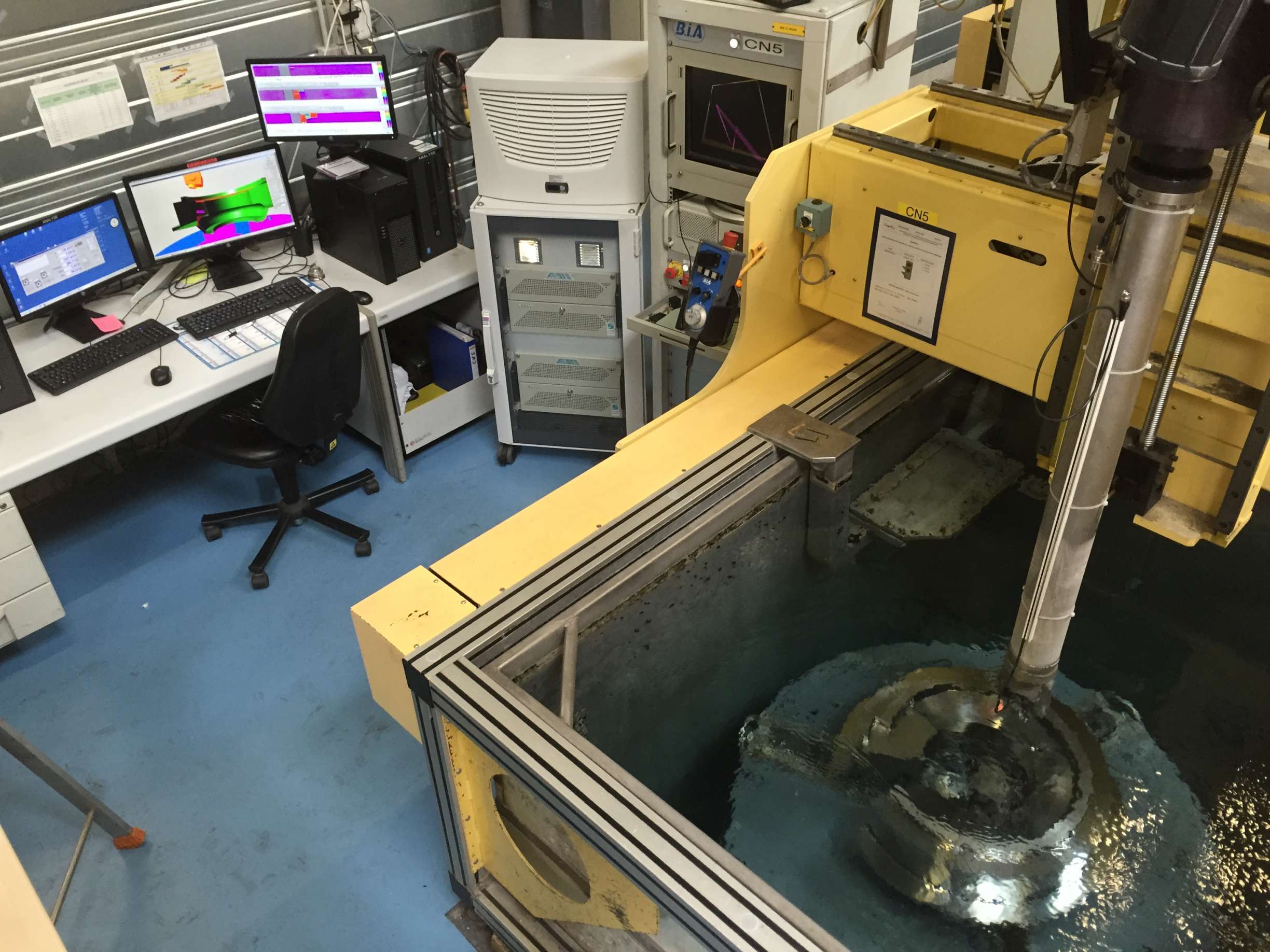

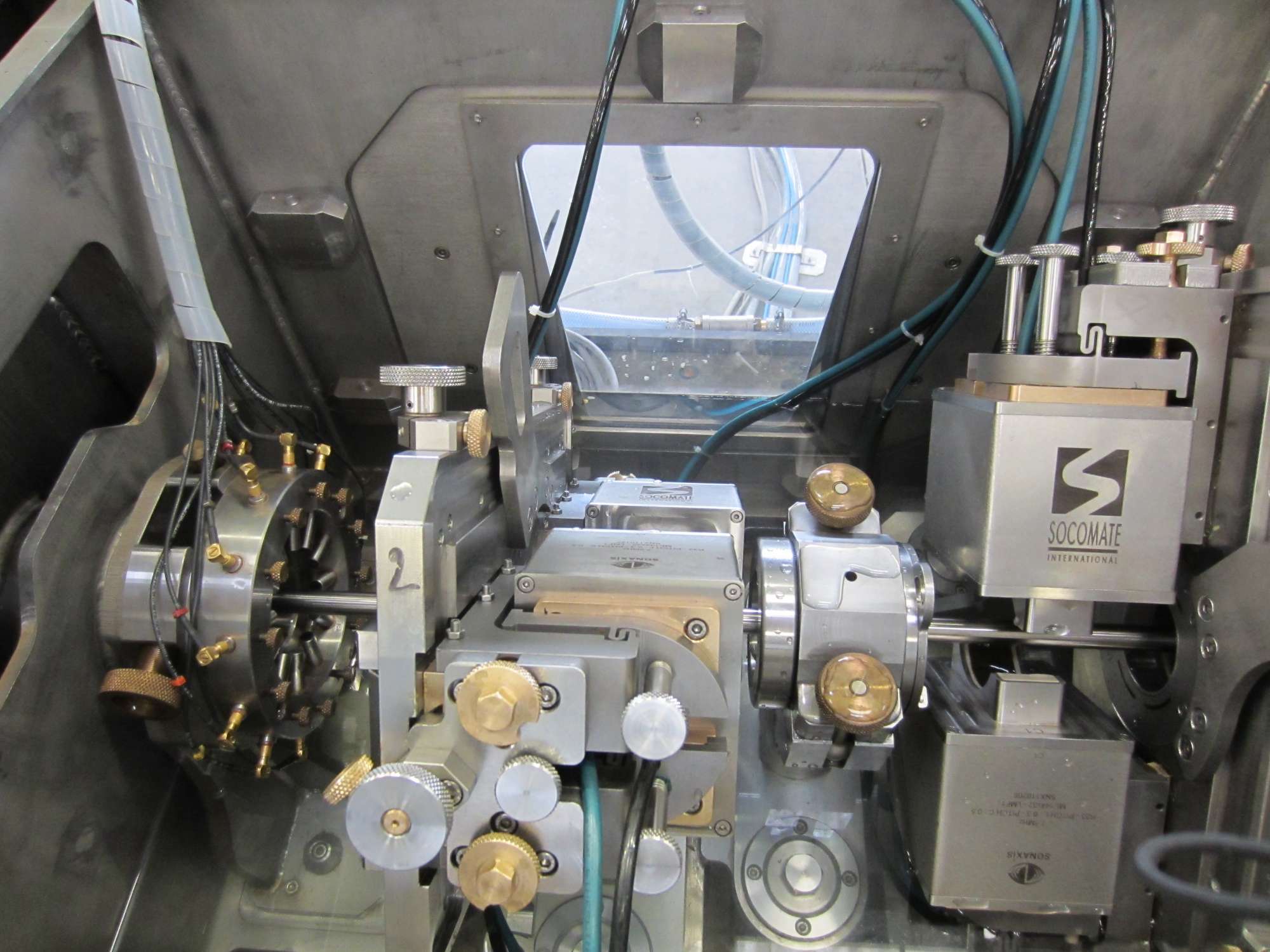

FAAST is a UT Phased Array (PAUT)

system which is much more powerful than conventional Phased Array system. Thanks

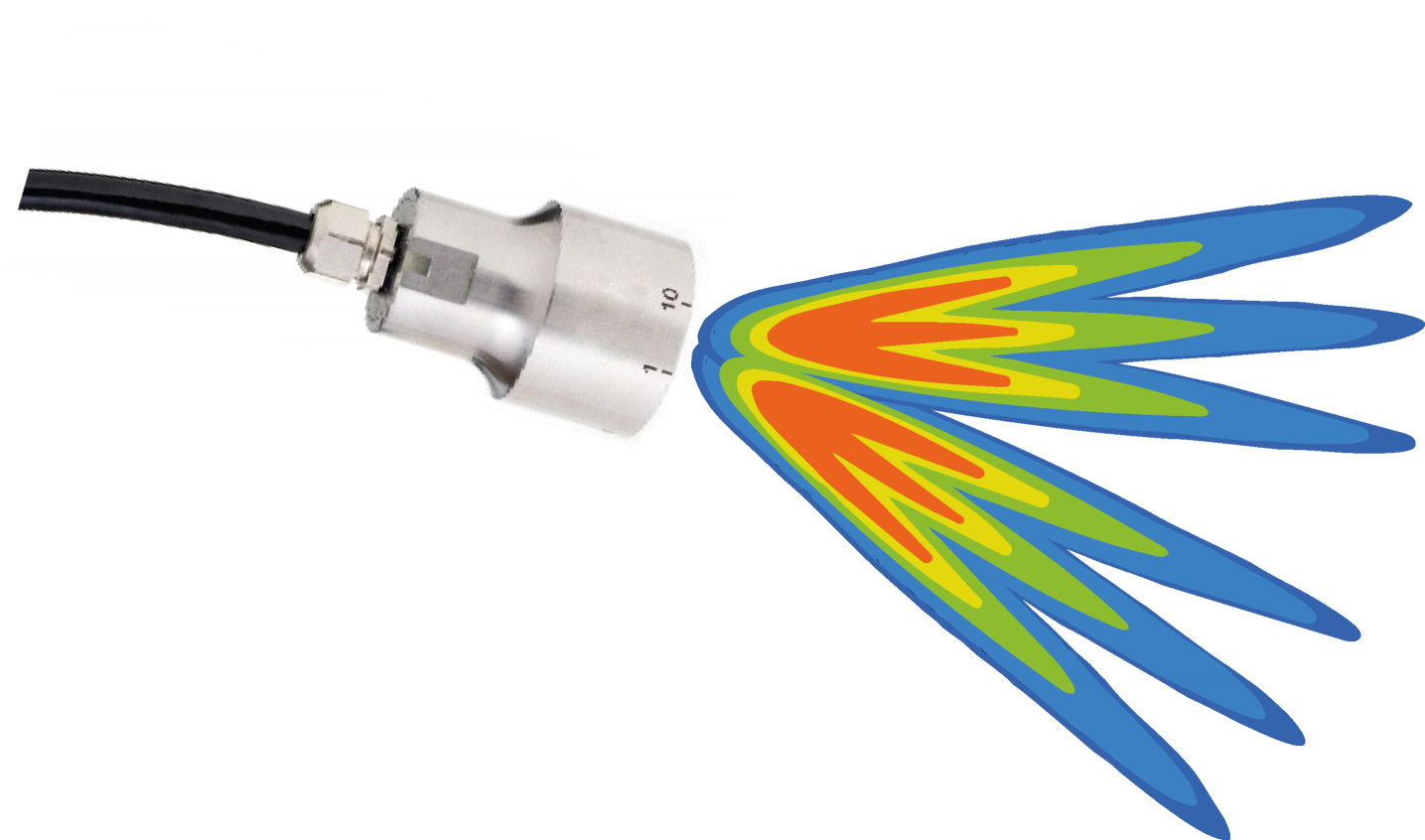

to its technology, the FAAST system has the capability to transmit multiple sound beams, multi-oriented and/or multi-focused,

through multi-element probes with only one

single shot, and then to process signals received from all beams in real time.

This patented technology (WO

03029808) revolutionizes the NDT environment when speaking about UT

inspection due to its high speed testing capabilities, as it is able to replace

several conventional Phased Array systems running in parallel. At higher

inspection speeds, it offers even more savings due to the reduction of Phased

Array probes, mechanical parts, maintenance and calibration time. Furthermore,

as well as FAAST increasing productivity due to its capabilities, it can also

be perceived as a very flexible system which can save you lots of money. As an

example, if today, a customer only requires Longitudinal and Transversal flaw

detection, perhaps tomorrow the requirement will be to inspect for oblique flaws. Simply by configuring the software settings regarding the delay laws of FAAST technology, one inspection configuration can be easily upgraded in order to meet with any new requirements.

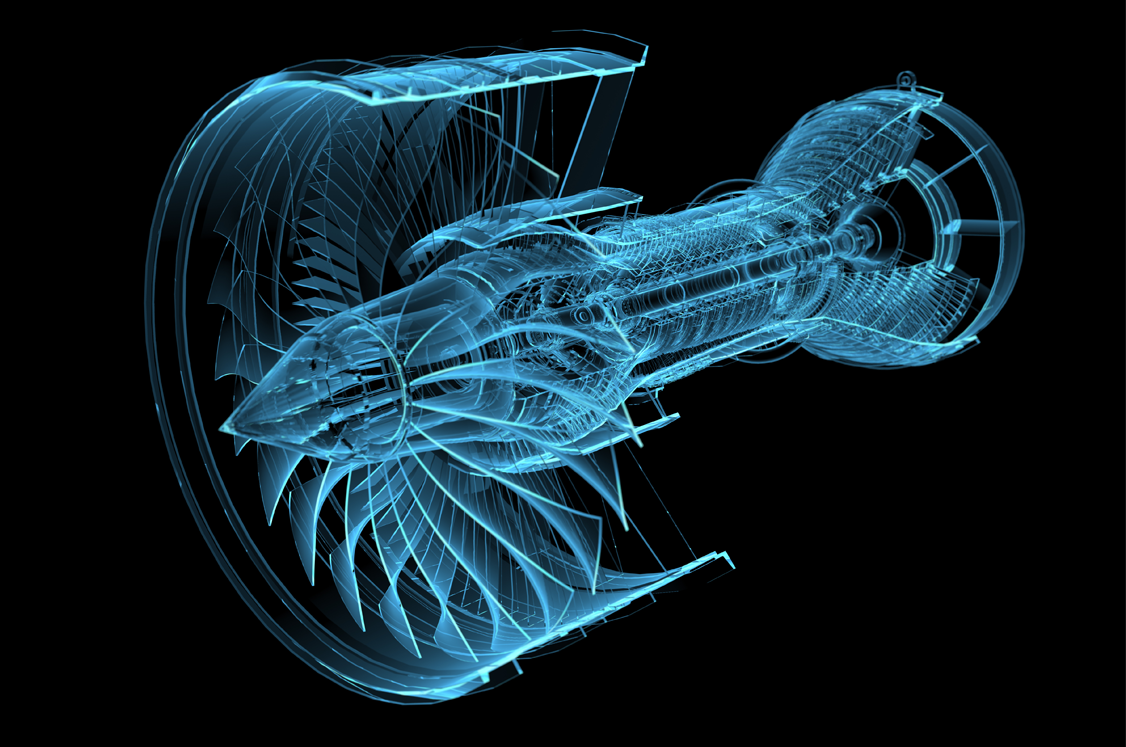

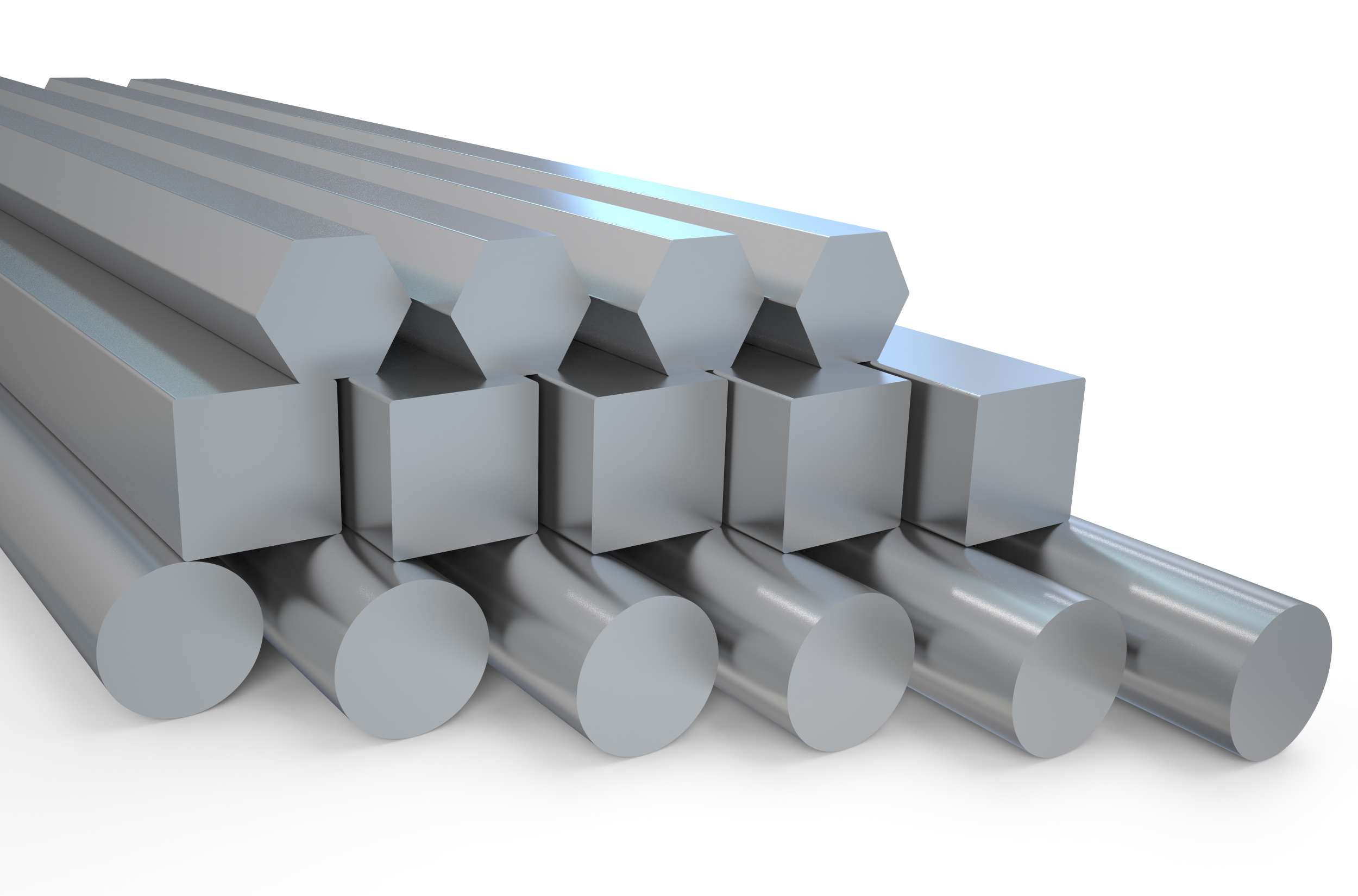

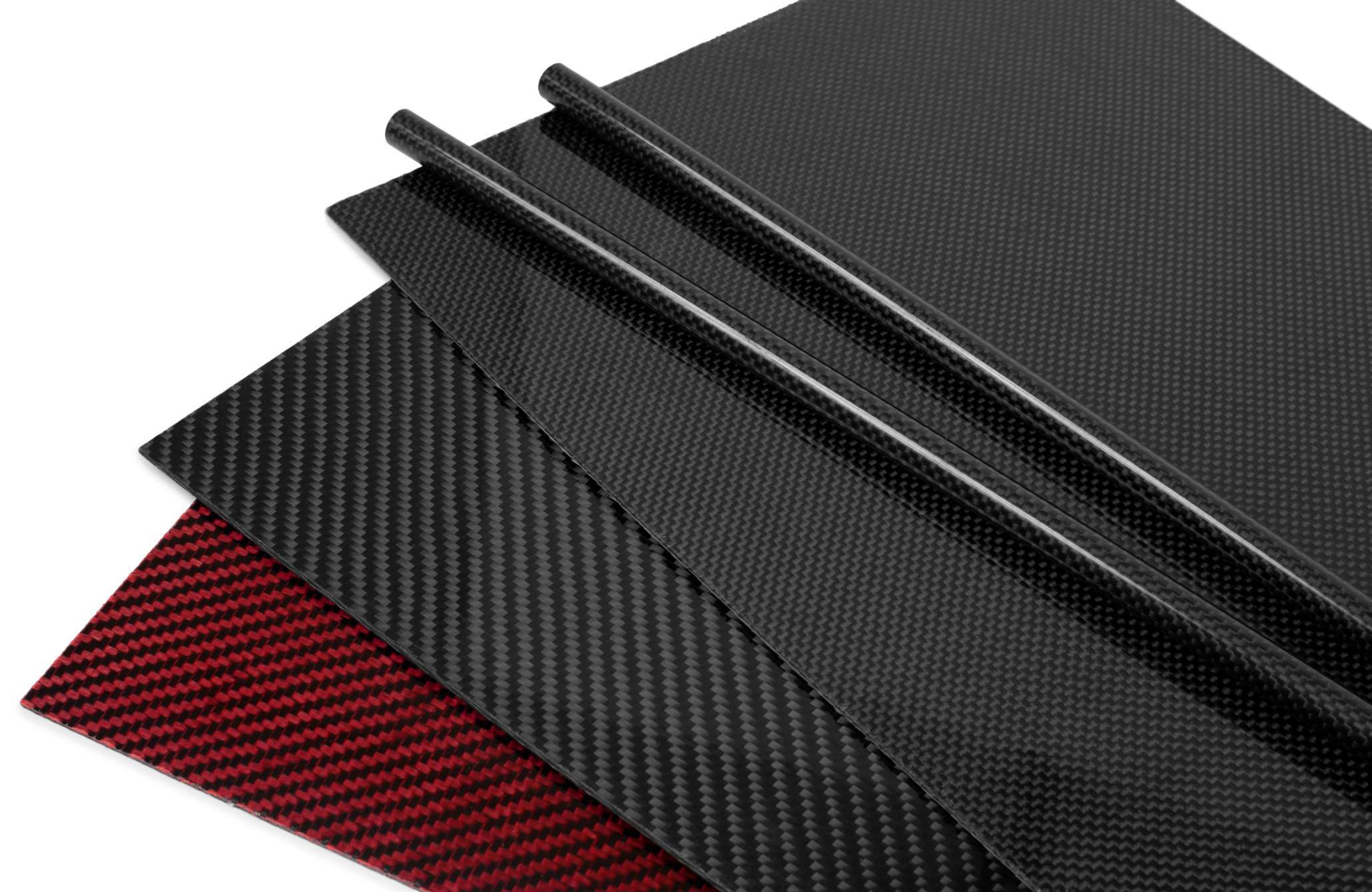

The FAAST technology can be applied to any type of application (Tubes, bars, plates, aircraft components, railroad, etc…), on different materials (Titanium, Aluminium, Steel, Special Alloy, Copper, Composites, etc…) and in any industries.

To demonstrate the system capabilities, we invite you to read the different possibilities that the FAAST Phased Array technology offers.

--------------------------------------------------------------------------------------------------------------------------------------------------