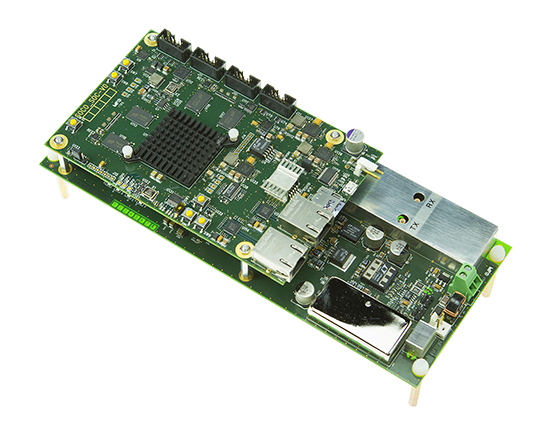

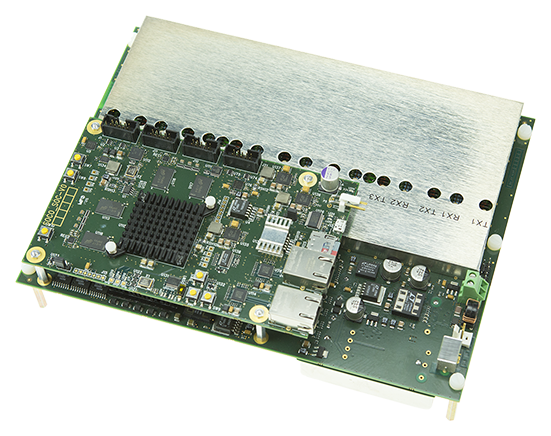

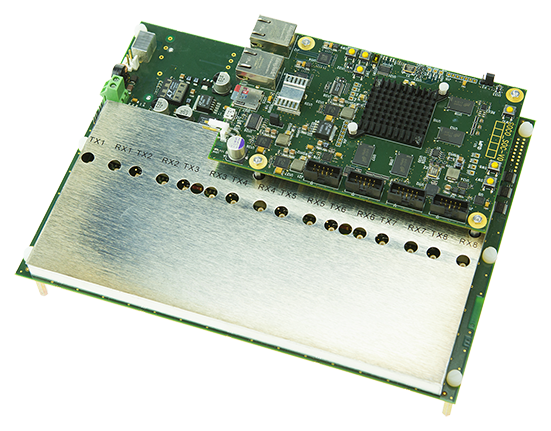

The Socoswift is the latest PAUT instrument from Socomate International for Phased Array Ultrasonic Inspection. It provides high tech features to answer the most demanding requirements for complex and high-speed inspections. Designed to be used in harsh environments, the Socoswift is perfect for automated inspection systems.

The real strength of this instrument is the SWIFT mode: you can use up to 4 active apertures or 1 large band emission, to then process in reception up to 4 virtual apertures in parallel for faster inspections without downgrading the resolution. SWIFT mode together with Dynamic Depth Focusing (DDF) method increase drastically the inspection speed of thicker materials.

This feature also offers high advantages for tubular goods inspection.

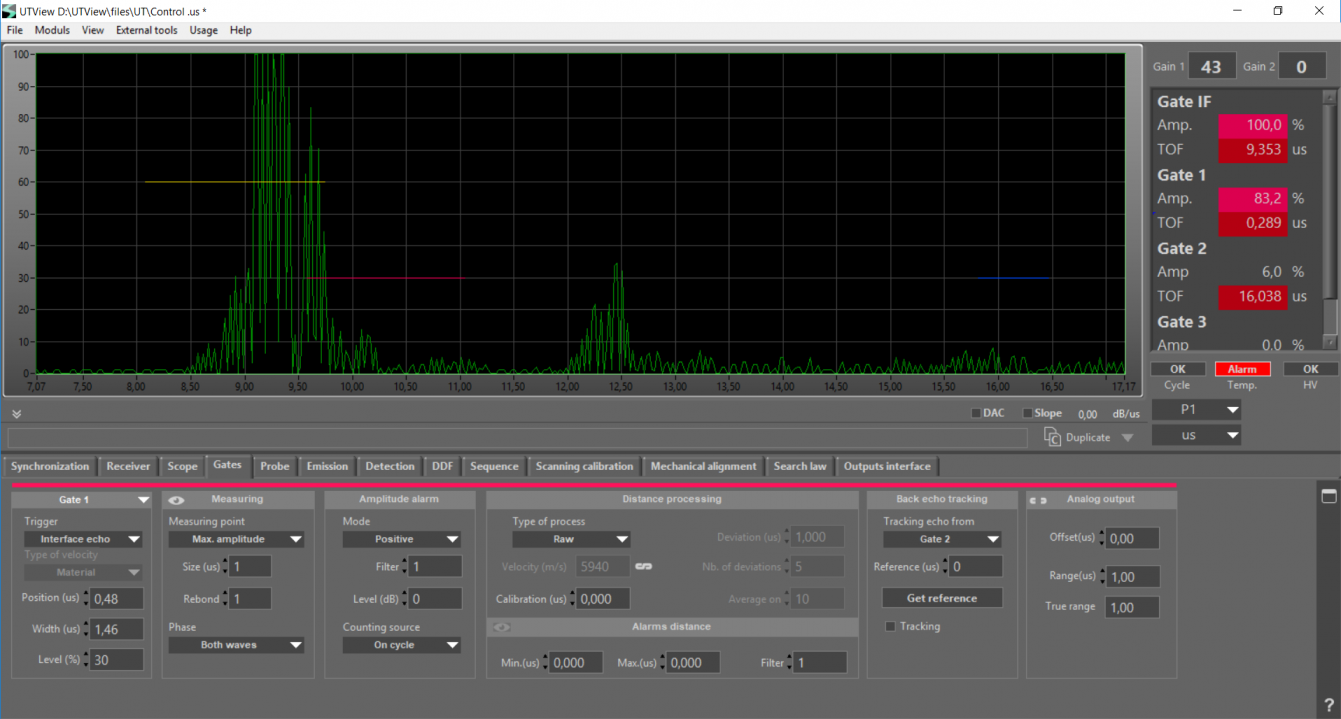

UTView

UTView is the API's delivered with all Socomate International's products and which is compatible with both conventional UT and PAUT instruments. The software provides an A-Scan view and allows to set all UT parameters.

UTView Software is provided with the source codes for you to integrate your Company logo or customize it as you like!

For more information, please feel free to contact us to get a full presentation.

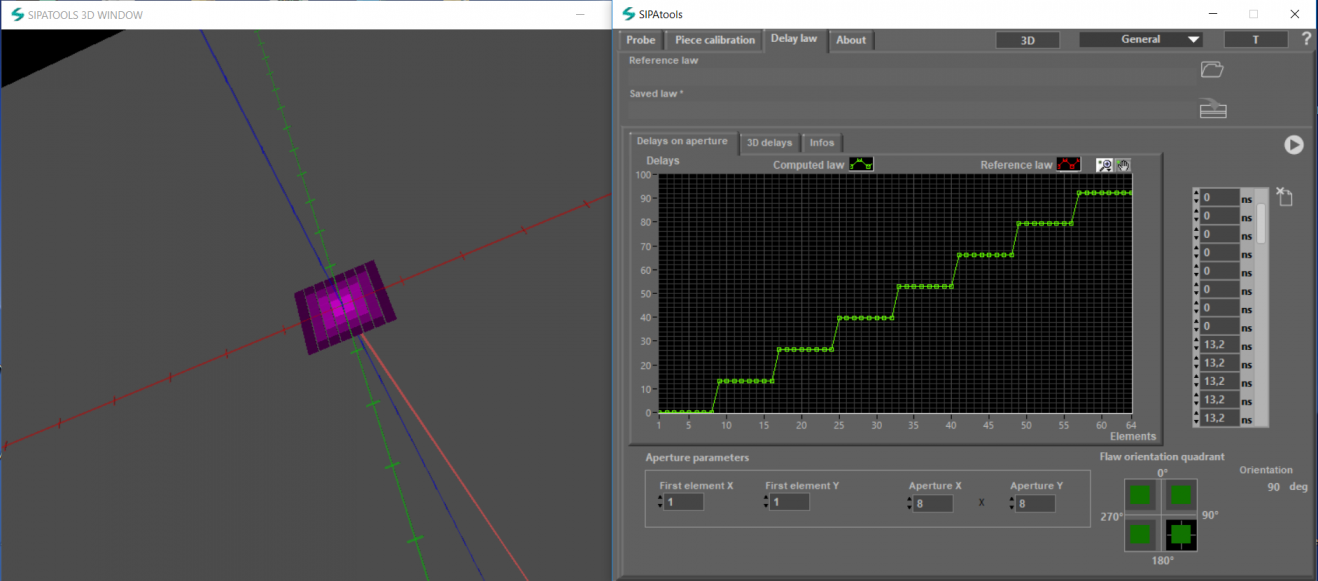

SIPAtools

SIPAtools is a specific software, developed by Socomate International and delivered with all Phased Array instruments used to define and calculate delay laws for any applications.

The software offers several possibilities:

Design a probe

2D and 3D view of the probe

Define the UT beam according to the part to inspect

Customized Application Software

Thanks to our open platform product, take advantage of the most complete DLL to develop your own customized software in any languages available that work on Win7 and Win10 operating systems, 32 and 64 bits.

The most standard languages such as C++, Visual Basic or LabView, benefit concrete example of coding with Socomate International DLL. The advantages of making its own application software is to perfectly meet your customers’ requirements instead of providing a standard and often complex software. Socomate’s DLL is compatible for both complete range of conventional UT and PAUT equipments, avoiding redundant work when involved in various applications. Having a common DLL for all products makes it more comfortable !

Wheel inspection

Fully automatic UT inspection of wheel-sets in work shops without dismantling the wheels from axles

Reference : SC Lead