Advantages

Cost - Effective PAUT inspection solution

Flexible Multi-OS environment

Operate across multiple platforms - Windows, Linus and Android - allowing versatile application development.

Reduced time for inspection

A comprehensive SDK and thorough documentation simplify the integration process, complemented by detailed ultrasonic imaging examples. The included advanced DLL allows integrators to directly embed a phased array delay-law calculator into their monitoring applications.

Applications

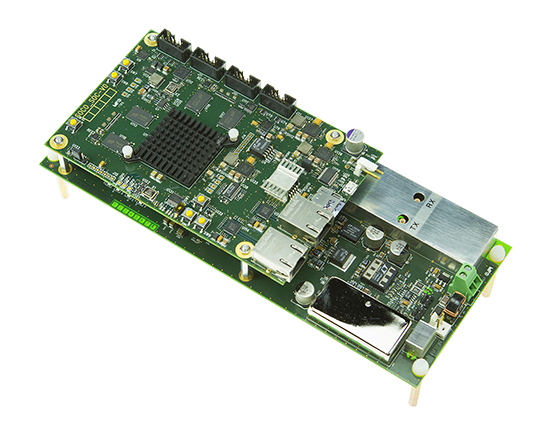

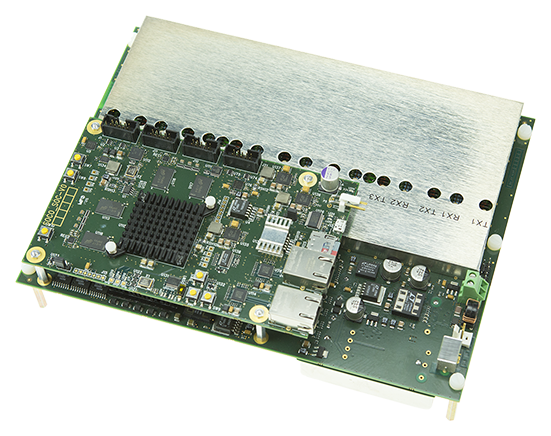

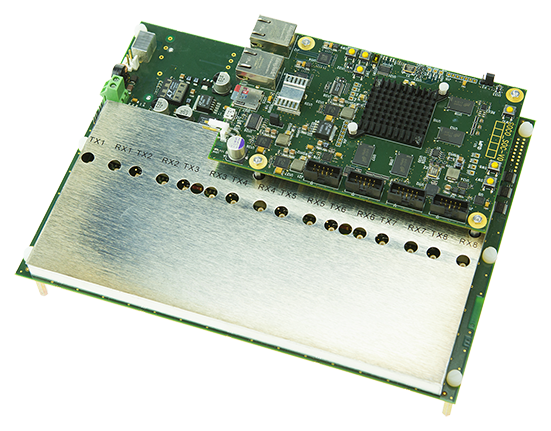

In-Line Automated Inspection (Gantry Systems, Immersion Tanks). For inspecting large or curved components, SPIKE offers precision and adaptability. It can handle challenging tasks such as inspecting composite aircraft panels or large slabs in immersion tanks. SPIKE’s compact design enables close sensor placement, preserving signal quality without long cables. Multiple boards (e.g., 3 x 16:64) can be stacked for larger configurations, all managed through a single control application..

Remote Inspections / On-Scanner (ROVs, Drones, Crawlers, Pigs, Scanners).The lightweight SPIKE board is ideal for mobile, autonomous platforms like drones, motorized crawlers, and subsea scanners. Compact and efficient, it enables ultrasonic inspections in confined or difficult-to-access environments.

R&D / Laboratory Development. With robust libraries and sample code for ultrasonic imaging techniques (e.g., phased-array, total focusing methods), SPIKE is a versatile tool for NDT research and development, allowing rapid prototyping and field-adapted solutions.

Field Inspection / Portable Flaw Detectors. SPIKE supports advanced flaw detection applications, making it an excellent choice for portable NDT devices. Ideal for high-volume inspections, it provides ease of deployment and intuitive operation in tools such as corrosion mapping (VENOM), rail inspection (EKORAIL and SOCORAIL), and thickness measurement (METIS).

Examples of SPIKE in action

VENOM : Automated corrosion mapping tool featuring SPIKE

EKORAIL & SOCORAIL : Inspection stick with SPIKE

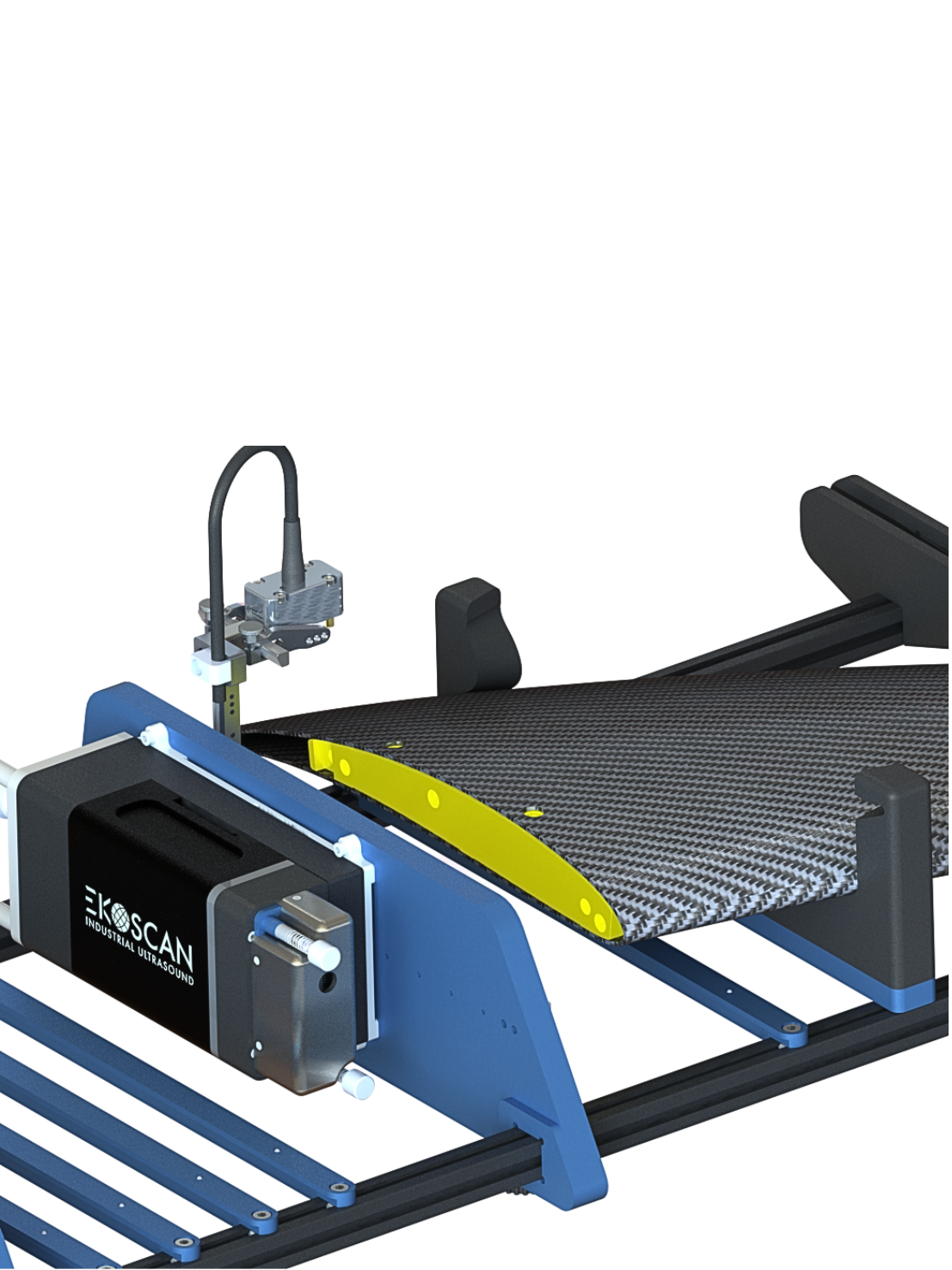

SPOILER : Inspection system for composite materials, assessing metallic bonding

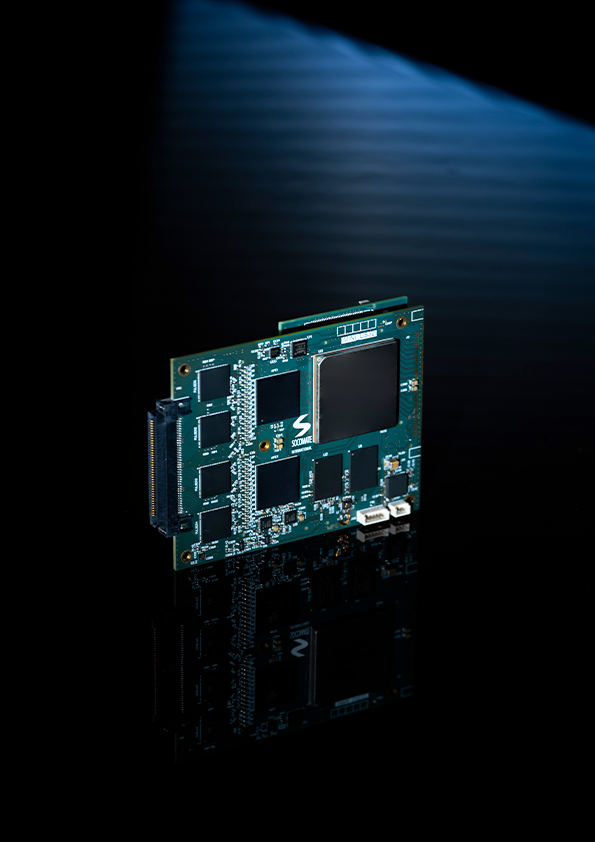

Technical Features